Revolutionize Food Packaging with Precision and Reliability: Discover Task Italy’s Machines

From dosing to labeling: tailor-made solutions for efficiency and quality at every stage of the process

WHO WE ARE

Over 20 Years of Experience: Your Trusted Partner for Food Packaging and Bottling

Since 2001, Task Italy has been supporting producers and distributors in the food and beverage industry with innovative solutions. With over 20 years of experience, we enhance productivity and reduce operational costs. Our philosophy is based on continuous improvement and listening to our customers' needs.

With Task Italy, you won’t just have a supplier, but a strategic partner that supports your growth, providing assistance at every stage of the process.

WHY CHOOSE TASK ITALY?

Tailor-Made Solutions and 360° Support for Your Food Production

Choosing Task Italy means relying on a partner that goes beyond merely providing machinery. We offer a comprehensive and personalized approach, ensuring solutions designed to meet your specific needs.

OUR MACHINES

Made in Italy Technology to Revolutionize Food Packaging and Liquid Bottling

Task Italy's machines represent the excellence of Italian technology applied to packaging and bottling.

From complete bottling lines for liquids to jar packaging solutions, every detail is designed to deliver efficiency, precision, and maximum food safety.

Our solutions stand out for their versatility: ideal for small, medium, and large productions, with endless customization possibilities to meet the specific needs of your business.

Liquid Bottling Systems

Linear Jar Filling Monoblock RTW600

A compact and automatic system designed for filling and capping glass or plastic jars with dense products such as honey, sauces, and jams. Ideal for small businesses looking to automate the packaging process with a sustainable investment.

Key Features

- Production capacity of up to 800 jars/hour

- Adjustable volumetric dosing system

- Automatic capsule loading magazine

- Easily adjustable for different jar formats and twist-off caps

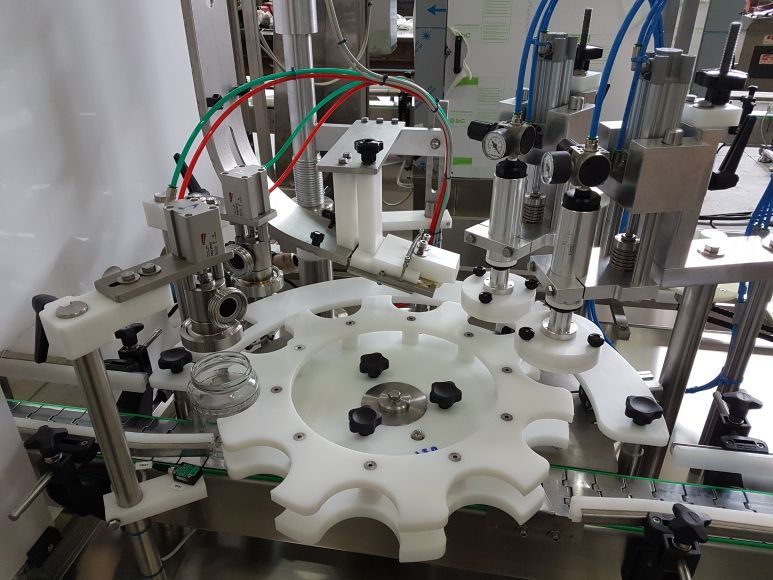

Rotary Jar Filling Monoblocks Models RTW1000-2000

A series of versatile machines with one or more dosing units, combining filling and capping for glass jars with twist-off closures. Suitable for dense and semi-dense products such as honey, jams, and spreadable creams.

Key Features

- Production capacity from 1,000 to 2,000 jars/hour

- Metal capsule distribution system

- PLC-based operation control

- Advanced safety systems

Monoblocks for Plastic Caps Series RT-PK

Ideal for bottles and containers with plastic caps, ensuring continuous and highly customizable production.

Key Features

- Production capacity from 900 to 2,000 bottles/hour

- Pick & place capping system

- Suitable for bottles, flacons, and containers

- Compatible with screw caps and press-on caps

Automatic Packaging Lines

Complete turnkey solutions ideal for packaging liquid and pumpable dense products. Perfect for sauces, mayonnaise, jams, and dairy products such as yogurt and milk.

These lines can include multi-head fillers, cappers, labelers, and packagers to meet diverse needs.

Key Features

- Production capacity of up to 6,000 pieces/hour

- Technical and commercial consulting for project development

- Custom line design with conveyor belts

- Integration of coding and traceability devices

Liquid Bottling Systems

Automatic Bottling Monoblock - Slim

The Slim Monoblock is the ideal solution for small wineries and artisanal producers. Available in versions with 5 and 7 filling valves, it offers automated and continuous production for wine, spirits, craft beer, and other still liquids.

Key Features

- Production capacity: up to 1,000 bottles/hour

- 5 or 7 filling valves

- Parallel bottle loading and unloading conveyors

- Compatible with bottles of various heights and diameters

- Nitrogen usage system for anti-oxidation and aroma preservation

Bottling Monoblocks for Liquids

A series of rotary monoblocks with filling turrets starting from 8 valves. Available in various configurations (gravity filling with light nitrogen pressure or vacuum filling) to accommodate any type of liquid, ensuring specific protection and efficiency needs.

These systems are complemented by automatic rinsers and cappers for all closure types.

Key Features

- Production capacity: starting from 1,000 bottles/hour, up to 6,000 bottles/hour

- Starting from 8 filling valves

- Multiple filling solutions for spirits, wines, edible oils, and fruit juices

- Single and double turrets for diverse capping requirements

- Availability of rinse solution recirculation kits

Isobaric Bottling Units

Isobaric bottling units are designed for filling carbonated liquids such as beer, sparkling water, cider, and sparkling wines. The isobaric system ensures maximum precision in fill level control and minimizes foam formation.

Key Features

- Production capacity: from 800 to 6,000 bottles/hour

- Pre-evacuation and nitrogen injection system

- Isobaric valves for filling carbonated liquids

- Suitable for glass and PET bottles

Automatic Bottling Lines

Complete turnkey solutions ideal for bottling all types of food-grade liquids, from alcoholic beverages to fruit juices and soft drinks.

These lines can include depalletizers, rotary fillers, cappers, labelers, and packagers to meet diverse needs

Key Features

- Production capacity: up to 6,000 pieces/hour

- Technical and commercial consulting for project development

- Custom line design with conveyor belts

- Adhesive or glue labeling in both linear and rotary systems

- Integration of coding and traceability devices

Semi-Automatic Lines and Equipment

A comprehensive range of professional semi-automatic machines designed for filling, capping, and labeling cylindrical and uniquely shaped bottles. Equipment is also available for small-scale production of sparkling wines using the traditional method.

Key Features

- Easy installation, setup, and operation

- Flexibility to work with different bottle formats

- Excellent quality/price ratio for small and medium productions

- Optimized quality for professional use

- Comprehensive range of machines to meet every need

Frequently Asked Questions

Frequently Asked Questions: Everything You Need to Know About Task Italy and Our Machines

What types of machines does Task Italy offer?

Task Italy provides a wide range of machines for food packaging and liquid bottling, including volumetric dosers, monoblocks for filling and capping, manual and automatic fillers, capping systems and labellers for bottles, jars, and containers. They can manage a wide range of food and beverage products, including sauces, honey, jams, yogurt, sauces, creams, oil, wine, beer, spirits, and fruit juices.

Are the machines customizable to my needs?

Absolutely. Before purchasing, our team conducts an in-depth analysis of your production needs. This allows us to recommend the most suitable machine and customize it if necessary. We can adapt production capacities, dimensions, container formats, and types of products processed.

Can the machines be integrated with existing production lines?

Yes, our machines are designed to be easily integrated into existing production lines. We provide consulting and technical support to ensure seamless integration.

Are the machines compliant with food safety regulations?

Yes, all our machines comply with the strictest food safety and hygiene regulations, both nationally and internationally.

What are the delivery times for a machine?

Delivery times vary depending on the complexity of the requested customization. Typically, we provide a precise delivery time estimate when the order is placed, ensuring transparency.

Are the machines easy to use?

Yes, our machines are designed to be user-friendly and intuitive. We provide training at our facilities and initial support to ensure your team can operate the machines independently and safely.

Do you offer after-sales support?

Certainly! Our support doesn’t stop with the delivery of the machine. We provide technical assistance, maintenance, and spare parts. Our team is always available to ensure your machines operate smoothly.

How can I obtain spare parts for the machines?

We offer a fast spare parts service to ensure the continuity of your production line. Common wear parts are usually always available in stock. You can contact our support team to request the parts you need.

Can Task Italy machines be exported to other European countries?

Yes, Task Italy exports its machines throughout Europe. Our machines comply with international standards, and we offer linguistic and technical support to ensure a seamless transition.

How can I request a quote or consultation?

Requesting a quote is simple. You can contact us via the form in the "Contact Us" section of our website. Our team will respond promptly to provide you with all the information you need.

Are the machines covered by a warranty?

Yes, all Task Italy machines are covered by a warranty. Warranty terms vary depending on the type of machine, but our team is always available to provide details and support if needed.

What payment methods do you accept?

We accept payments in euros via bank transfer.

Contact Us: We’re Here to Help!

Whether you want to request a quote or ask for information about our machines, our team is always at your disposal. Fill out the contact form or call us directly. We’ll be happy to answer all your questions.